Description

To guarantee product quality and protect the reputation of your brand, the following are important standard procedures for garment evaluation:

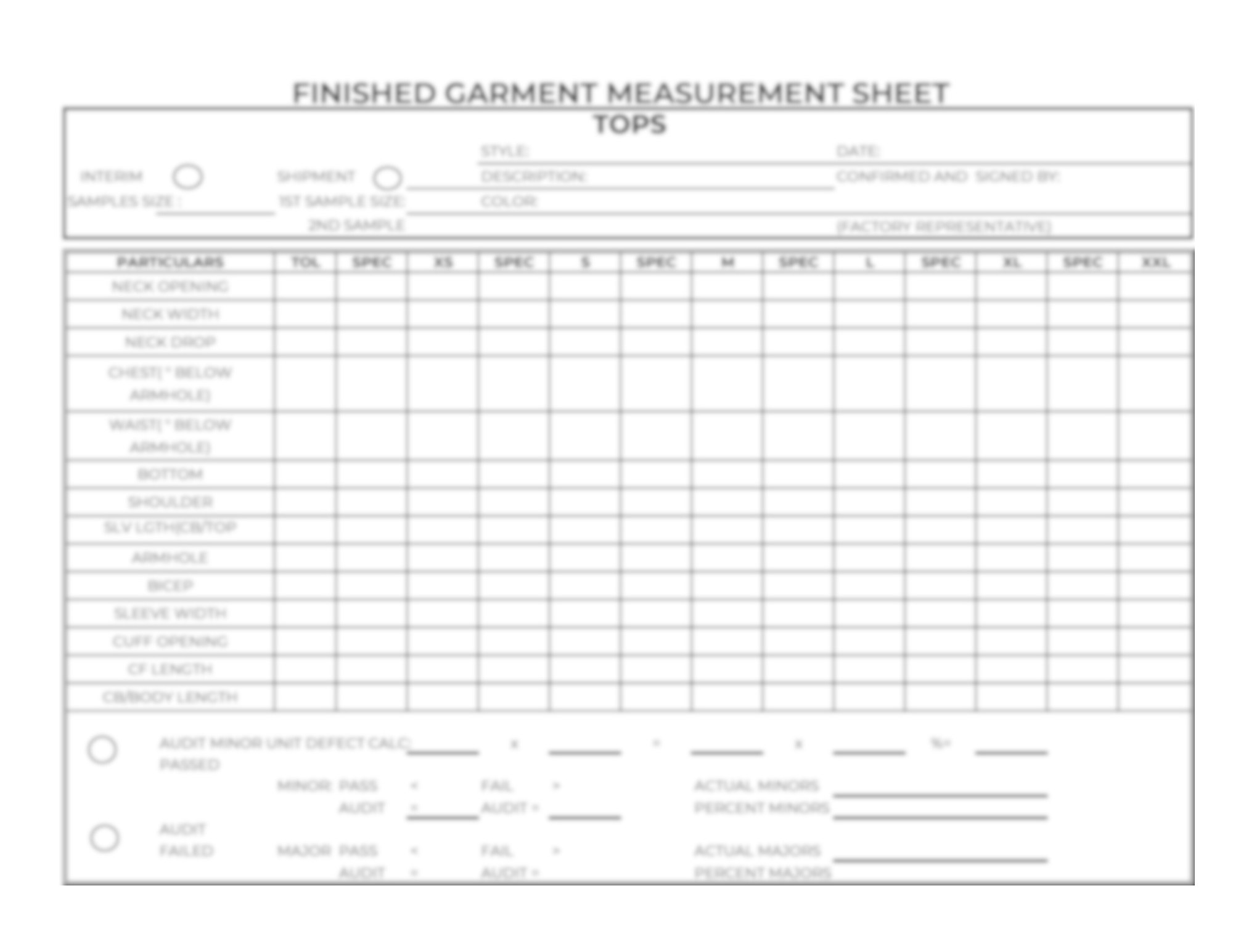

- Measure Garment Dimensions:

- Ensure that garment dimensions correspond to specified sizes.

- Though efficient manufacturing processes are not immune to discrepancies, it is essential to maintain consistency in measurements.

- Verify the Accessories’ and Closures’ functionality:

- Check if zippers, buttons, and other fasteners are operating correctly.

- Ensure that decorations, labels, and tags are attached appropriately to accessories.

- Check for accurate labelling and packaging:

- Make sure clothing is properly wrapped for delivery.

- Verify hangtags, labels, and care instructions for their accuracy and conformity.

- Test Fabric Quality:

- Test the fabrics to ensure they meet quality standards.

- Check the fabric for flaws, stains, or inconsistencies.

- Report Any Quality Issues:

- Write down every defect found during the inspection.

- Establish levels of urgency so that problems can be quickly resolved.

Using a garment measurement sheet offers several benefits during inspection:

- Accurate Sizing: Measurement sheets ensure garments comply with specified sizes, providing customers a constant fit.

- Quality Assurance: Early discrepancy detection will stop defective products from reaching the customer.

- Reduced Returns: Accurate sizing reduces returns from customers because of clothes that don’t fit well.

- Efficient Production: When guided by measurement sheets, production minimizes mistakes and rework.

- Brand Reputation: Customer satisfaction and brand trust increase by consistency in size.

Reviews

There are no reviews yet.